Wire binding machine with hole punching function PBW580 for notebook

wire binding machine and hole punching inline PBW580 Description:

PBW580 machine include two function, wire binding function and paper hole punching function,total 3 actions,notebook feeder,punch,then push finger catch punched notebook to wire binding part,then close wire o,final be deliver to conveyor. Or calendar feeder,punch,then push finger catched calendar to wire bind part,then drop hanger,final be deliver to conveyor.

Notebook :Stacker → Punching → Hanger → Closing → Delivery Conveyor

Calendar: Stacker → Punching → Closing → Delivery Conveyor

Wire binding& punching inline machine Application:

PBW580 is advanced machine in wire o bind finish area,could be used in produce notebook,desk calendar and calendar wire o production.

Wire binding and hole punching in Notebook area :

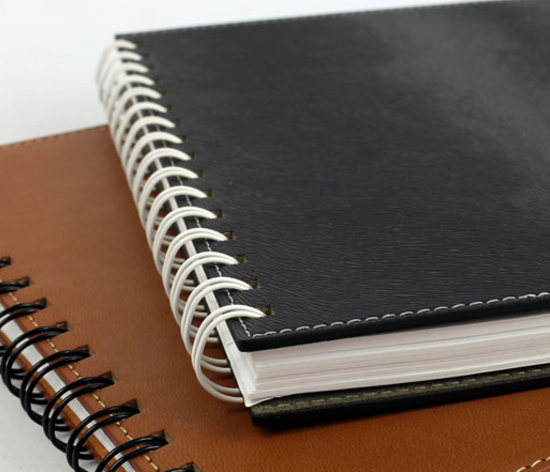

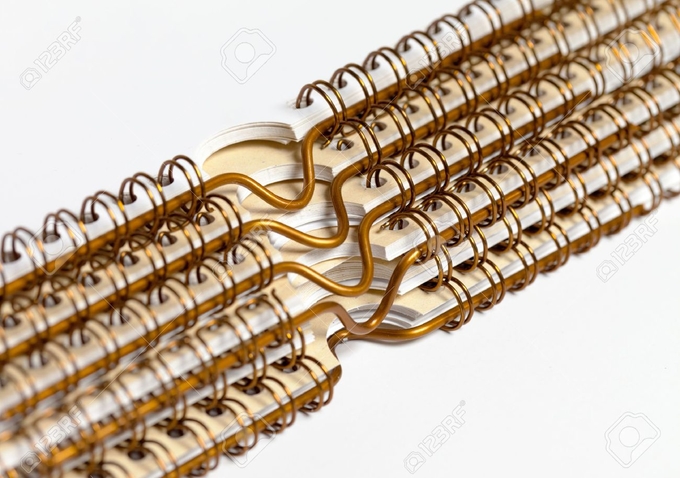

Have two operate situation,notebook with same bind edge like below picture

Video upload in youtube :

https://www.youtube.com/watch?v=ipgABRhvep8

If notebook with same size (cover and background size same with inner paper size), only need one people operate.

Notebook with differ size (cover bigger than inner paper),like below picture

Video upload in youtube :

https://www.youtube.com/watch?v=HC0UCRt8dQQ

If cover bigger than inner paper,need punch cover advance,and then do video show,need two people together

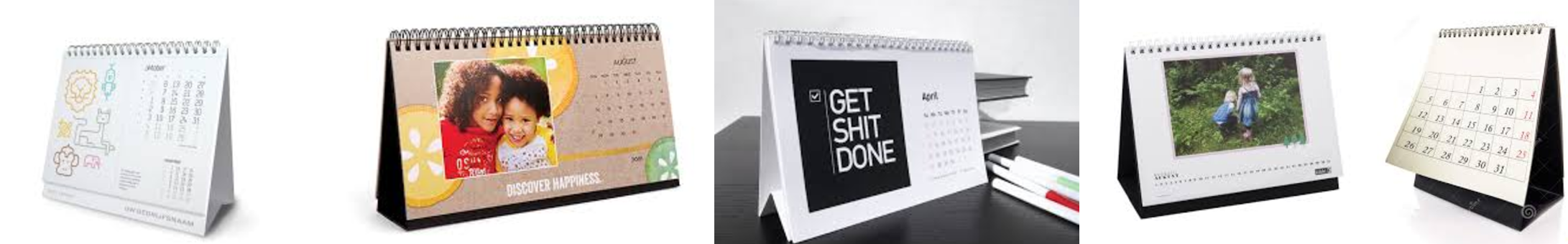

Wire o bind &punch in desk calendar area

In common,hard Cover could be punch with inner paper together.so only one people could handle.

Video do bind& punch for desk calendar

https://www.youtube.com/watch?v=_WJuOkT33uc

Wire o bind &punch in calendar area

Calendar is a traditional gift ,if you are manufacture,please do not hesitate to contact us,this machine you deseve it.

Video wire o bind&punch for calendar:

https://www.youtube.com/watch?v=dstf4hwGd-Y&t=2s

Machine Technical data:

| speed |

600-1500 production/hour |

| Air pressure |

5-8 kgf |

| Wire o diameter |

1/4-3/4 |

| Max size of paper |

580mm x 800mm |

| Min size of paper |

120mm x 105mm |

| Max punch thickness |

5 times total 15mm |

| Electric power |

3ph 380 |

| Max punch edge size |

580mm |

| Max bind edge size |

580mm |

Machine advantage:

1.It combines auto punching and binding in one machine to save labour cost and improve production effciency

2.One machine could handle notebook,desk calendar,calendar bind and punch work

3.Not only one machine do bind and punch ,could be use seperate do bind or seperate do punch.

4.Auto collect production and could be set in touch screen for numbers books finished then move

5.If customer choose hanger device,could be do straight hanger and auto drop.

6.Complete Punch mould include two small punch moulds,and small punching moulds could change position.